HOLD Machinery: Professional Manufacturer

of Custom Furniture Production Lines

HOLD Machinery is a high-tech enterprise

specializing in woodworking machinery design, production, sales, and service. With

an expert design and development team, HOLD focuses on the development of automated

panel furniture equipment, providing comprehensive factory planning and

automated production line solutions for furniture enterprises. At present, HOLD

has served furniture and wooden door companies in more than 70 countries and

regions worldwide, establishing an extensive global sales network.

With 20 years of experience in the

furniture equipment industry, HOLD's R&D team consists of skilled engineers

and designers with profound knowledge and innovative capabilities. From initial

table saws and drilling machines to complete panel furniture factory equipment,

and then to comprehensive factory line solutions, the brand consistently

follows market demands to provide complete solutions for customers.

At present, the brand has more than 200

issued and pending patents, including more than 70 invention patents and more

than 130 utility model and design patents. This demonstrates HOLD's core focus

on technological innovation and its industry-leading technical strength.

Guangdong Production Base & Hubei

Production Base. SOURCE: HOLD Machinery

Since 2022, HOLD’s Hubei production base

has officially begun operations. HOLD’s Guangdong and Hubei production bases

cover a total area of 100,000 square meters, and are equipped with a complete

supply chain system and large-scale production capabilities, effectively

controlling costs and providing customers with high-quality products.

In 2023, HOLD developed a flat intelligent

three-dimensional sorting warehouse for panel furniture. Traditional manual

sorting methods were inefficient, space-consuming, and costly, while

bookshelf-style sorting improved efficiency but had low online rates.

Therefore, HOLD began to developed a flat intelligent three-dimensional sorting

warehouse that greatly improving sorting efficiency, required minimal space,

and accommodating board materials equal to or larger than 250x50mm. This

three-dimensional sorting warehouse for panel furniture has gained industry

recognition and is currently in use in Russia and the United States.

Six-sided Drilling Workshop, Electronic Saw

Workshop, Edge Banding Machine Workshop. SOURCE: HOLD Machinery

HOLD offers over 100 models of cutting,

edge banding, drilling, and wooden door equipment. The company can match the appropriate

woodworking equipment according to customers’ capacity and space requirements,

while also providing factory-wide line solutions and software integration.

HOLD’s self-developed flexible production

lines help manufacturers solve bottleneck issues by providing customized

whole-factory services in terms of processes, labor, material savings, and

space utilization to meet production needs.

Customer Cases. SOURCE: HOLD Machinery

For custom furniture manufacturing, HOLD

CNC has developed three complete sets of flexible production line solutions:

economic, professional, and composite. Each line includes design breakdown

optimization, CNC cutting centers, fully automatic edge banding, CNC drilling,

and other process equipment. These lines can achieve 8-hour production volumes

of 200-280m2, 300-500 m2, and over 500 m2 respectively, suitable for factories

of different scales. The comprehensive and professional interconnected

equipment supports various modular combinations, enabling automated intelligent

manufacturing for different requirements.

HOLD’s intelligent production lines

leverage machine vision, IoT, sensors, and other technologies to achieve

automation, traceability, and monitoring of the production process. This allows

companies to digitize and informatize every aspect of production, quality

assurance, and logistics management, improving the overall efficiency and

quality of the supply chain. These solutions create greater business value for

enterprises and provide home furnishings companies with specific, implementable

solutions.

From single machines to

interconnected lines, from interconnected lines to workstations, increasingly

lengthy intelligent automated production lines provide strong support for the

home furnishing manufacturing industry’s transition from “manufacturing” to

“smart manufacturing.” In addition, HOLD has a professional 24-hour after-sales

service team, providing one-stop professional services for furniture

manufacturers.

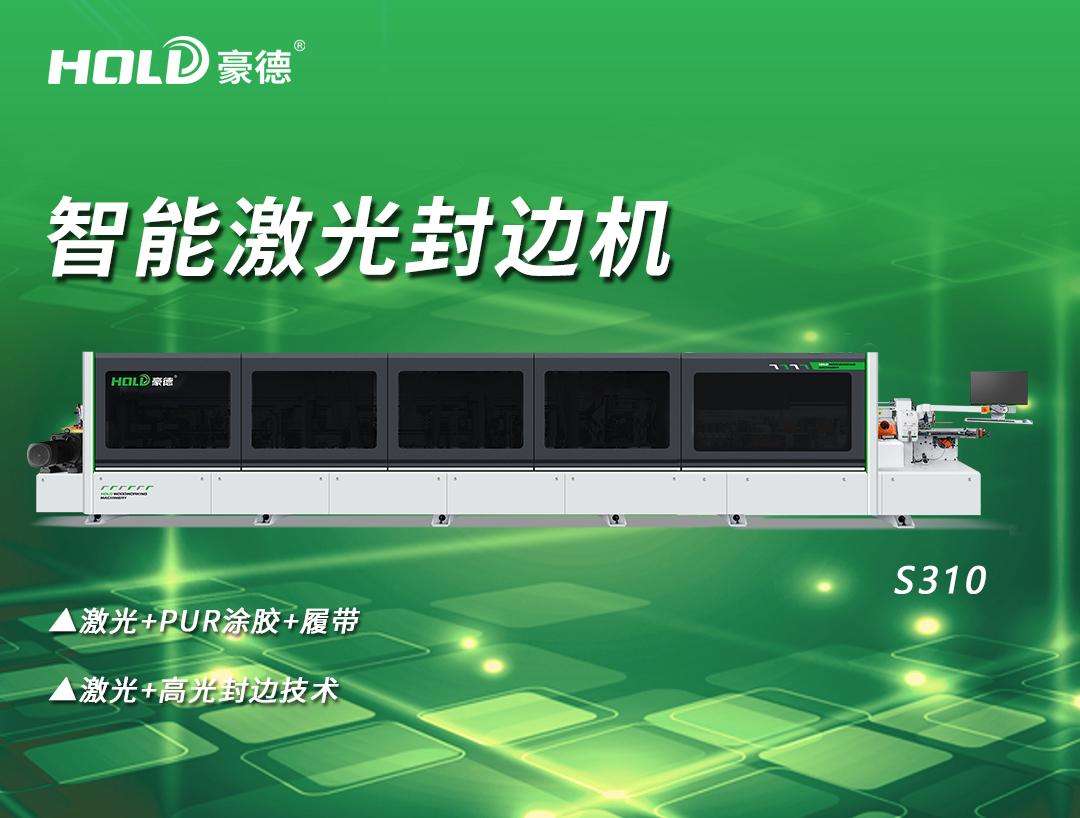

HOLD’s intelligent laser edge banding machines adopt advanced laser

technology and feature high cutting precision, high speed, and low energy

consumption. These machines not only meet customers’ basic requirements but can

also be customized according to special needs, providing more personalized

solutions. HOLD’s intelligent laser edge banding machines have been recognized

widely in the international market, and have become one of HOLD’s key

competitive advantages.

S310 Intelligent Laser Edge Bander S310, Laser

+ PUR Gluing + V-Belt, Laser + High-Gloss Edge Sealing Technology. SOURCE: HOLD

Machinery

HB621GKH6 CNC Six-Sided Drilling and

Milling Center HB621GKH6, Servo Rotary Tool Changer, Independent Cross-Side

Milling Tool Magazine. SOURCE: HOLD Machinery

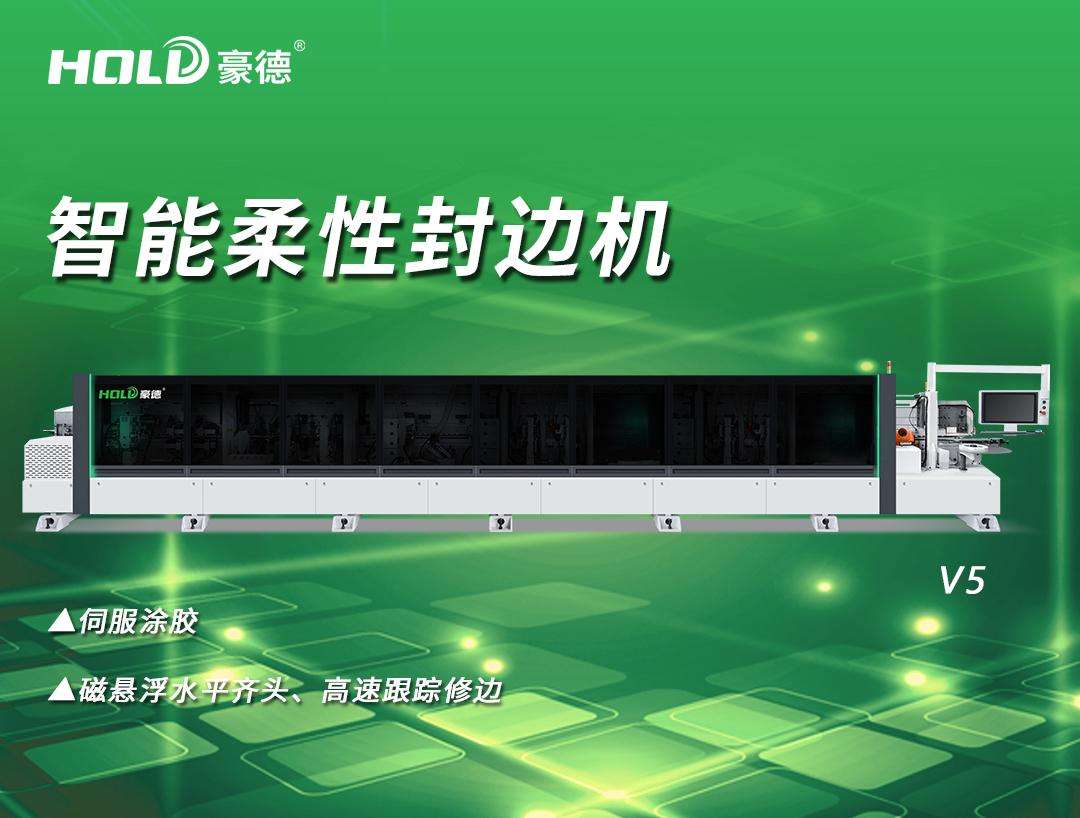

V5 Intelligent Flexible Edge Bander V5,

Servo Gluing, Maglev Horizontal End Trimming & High-Speed corner rounding.

SOURCE: HOLD Machinery

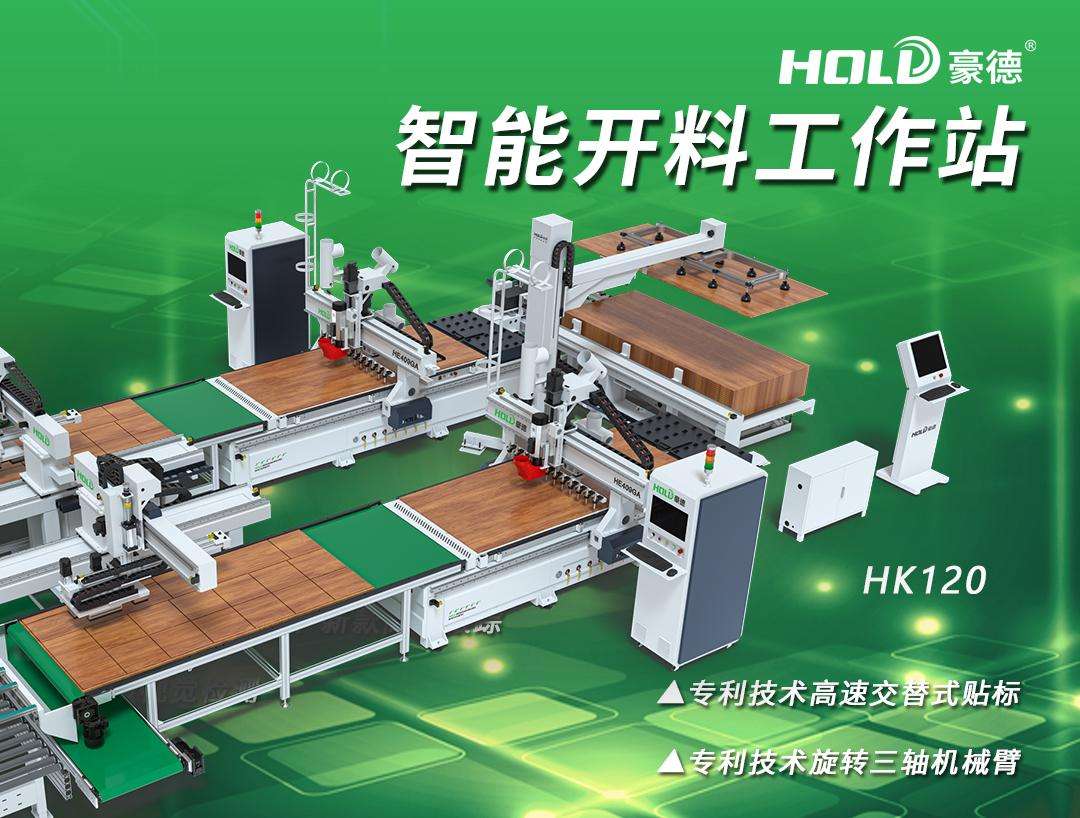

Intelligent Cutting Workstation, Patented

High-speed Alternating Labeling Technology, Patented Rotating Mechanical Arm.

SOURCE: HOLD Machinery

In addition to intelligent laser edge banding

machines, HOLD has launched several other flagship products. For example, HOLD’s

high-speed drilling machines feature high drilling speed, high precision, and

excellent stability, suitable for processing various complex materials. These

high-speed drilling machines have achieved outstanding success in both domestic

and international markets.

As main drafting unit,HOLD undertook the

drafting of the industry standard of “CNC Woodworking Panel Saw” and “CNC

Woodworking Five-sided Drilling Machine”. SOURCE: HOLD Machinery

In the future, HOLD will continue to

increase investment in R&D, strengthen cooperation with renowned

enterprises and research institutes at home and abroad, jointly promote

technological innovation and product development, and introduce more products

that meet international market demands. HOLD warmly welcomes international

buyers in search of quality suppliers at CIFF Guangzhou to experience the

extraordinary charm of “Made in China” and the outstanding speed of “Chinese

efficiency”!

Save the date: Mark your calendars

for the 55th China International Furniture Fair (Guangzhou), to be held at

Guangzhou Pazhou.

From 18 to 21 March, 2025, the first phase

will feature Home Furniture, presenting all areas of home furnishings. The

second phase, from 28 to 31 March, will spotlight the Office and Commercial

Space, the world's largest exhibition dedicated to office furniture and

commercial design.

Register now for your free e-entry code on

our website!