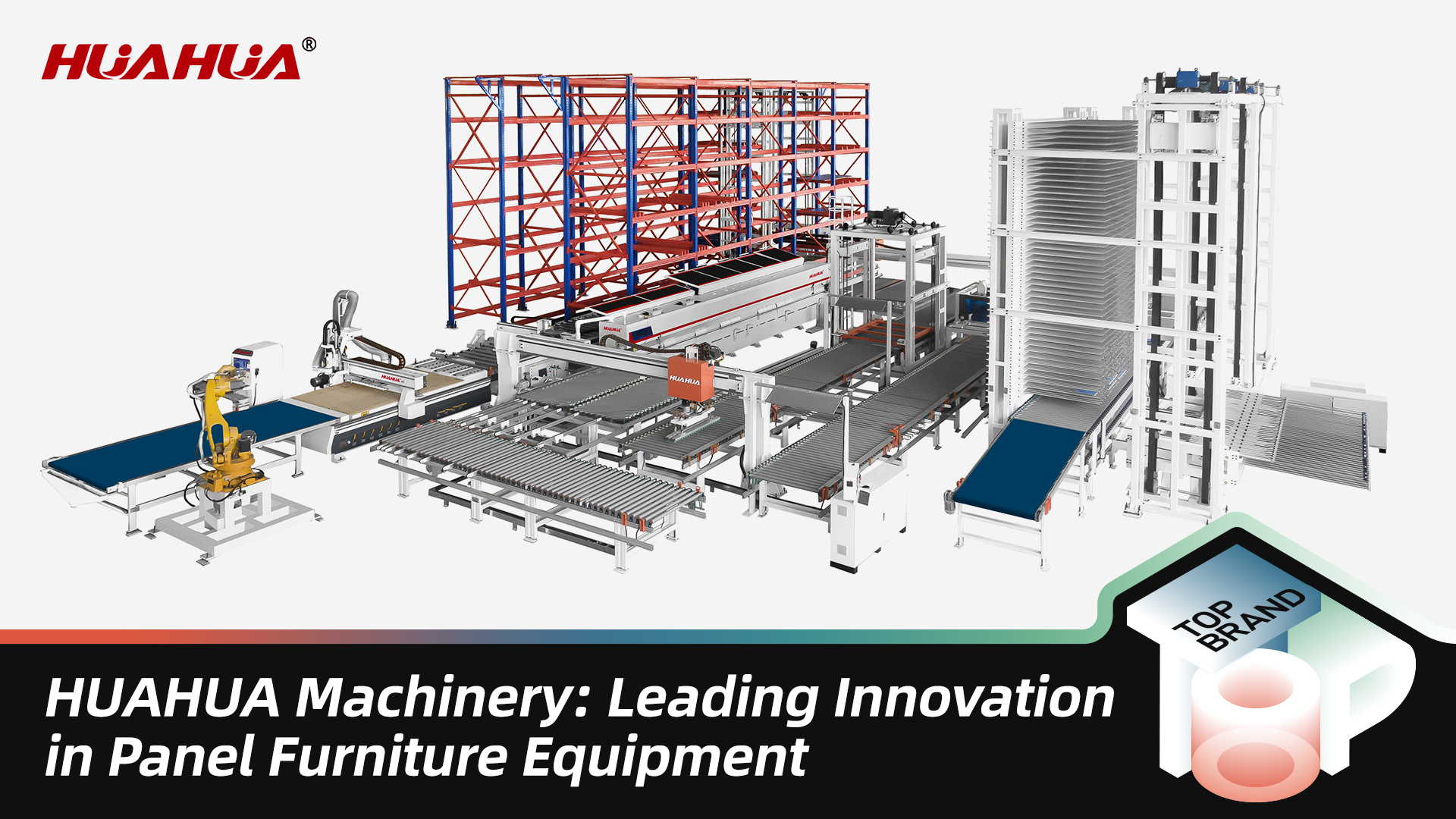

HUAHUA Machinery: Leading Innovation in

Panel Furniture Equipment

From its headquarters in Lunjiao, Shunde–China’s

woodworking machinery hub–Guangdong Changsheng Machinery Manufacturing has

established two distinguished brands: HUAHUA Machinery and Yalin Machinery. The

company specializes in advanced numerical control equipment, including

computer-controlled panel saws, CNC cutting machines, edge banding machines,

six-sided drilling and milling centers, and intelligent production lines. This

focus drives the industry forward through information-intelligent furniture

production models.

HUAHUA invests in intelligent technologies

to develop equipment with smart control, automated production, and data

analysis capabilities, enhancing production efficiency and quality. In

customization, they focus on strengthening R&D for equipment tailored to

diverse client needs, providing flexible solutions. Their establishment of an

efficient R&D team and streamlined processes shortens product development

cycles, enabling swift launches of innovative equipment that meet market

demands.

High speed intelligent computer beam saw: According to the thickness of the panel, the sawing stroke can be automatically positioned to reduce the idling time, and the speed of the saw carriage is 120m/min. SOURCE: HUAHUA

Drilling and cutting integrated machine: Processing

big and small panels. Labeling and drilling at first and then cutting. No need

to flip panels. One-time positioning and independently developed nesting

function. Match well with the common software on the market. SOURCE: HUAHUA

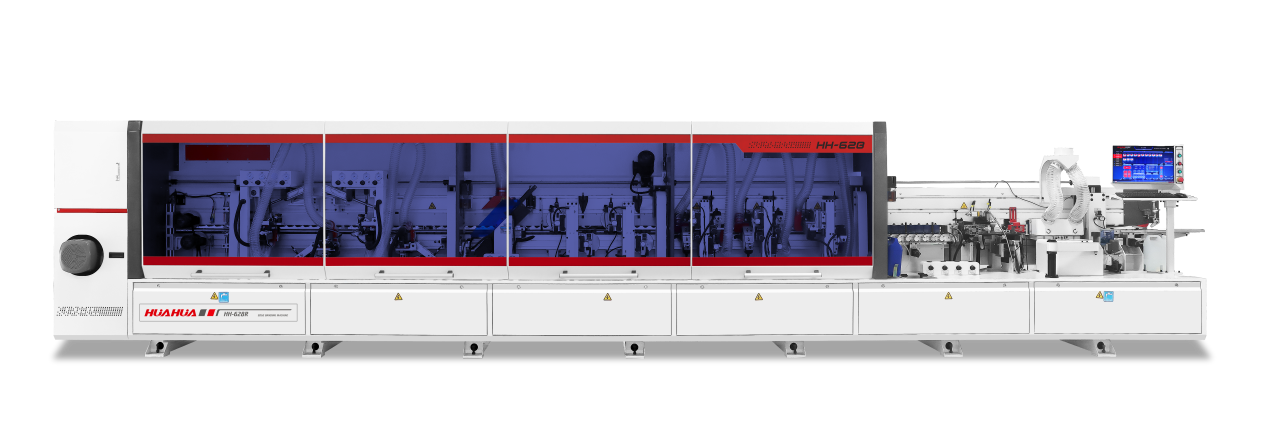

HH-628R-High speed linear aluminum

honeycomb panel edge banding machine: Specially designed for aluminum honeycomb

composite panels environmentally friendly and energy-saving, one machine can be

used for multiple purposes. One strong press wheel and nine rubber wheels,

automatically remove the residual glue; The new high-speed four-corner rounding

action is gentle, and it is not easy to scratch the panel during processing,

making the edge banding effect smoother and more beautiful.SOURCE: HUAHUA

HH-698RLK(50)-High speed linear edge

banding machine (Narrow side): Narrow panel edge banding, upgraded high-end

configuration, greatly improve the edge banding effect; Six wheels pressing and

three wheels pressing. Multiple rubber wheels combination and repeated pressing

mode. SOURCE: HUAHUA

Companies from different countries have

unique attributes and distinctions, necessitating tailored solutions to address

varied customer needs. HUAHUA is focusing on this challenge, aiming to provide

versatile offerings that meet diverse demands.

An example is HUAHUA automated edge banding

series:

Intelligent Edge banding for Mass

Production: Select from various solutions based on site, capacity, craft, and

process requirements. Modular workstations offer flexible support for multiple

combinations, optimizing production efficiency to suit specific needs.

HUAHUA Machinery’s Star Product: The

Six-sided Drilling Machine, widely recognized in the market for exceptional

performance and broad applicability.

Double drilling heads automatic six sides

CNC drilling machine (With 7+1 ATC tool magazine) 7 straight handles+1 side

milling. Able to process horn handles, embedded handles, lamello, and various

invisible parts etc. SOURCE: HUAHUA

By developing such versatile and adaptable

products, HUAHUA aims to set new benchmarks in the furniture hardware industry

and continue to meet the ever-evolving needs of its global clientele.

Since its establishment, HUAHUA has

consistently focused on driving innovation in the field of panel furniture

equipment. Starting from 2011 with the production of such equipment, HUAHUA

introduced the concept of unmanned production lines in 2018. Over nine years,

they successfully integrated standalone products into the entire production

line, forming a solid technological and talent reserve. This development

enhanced competitiveness and provided high-quality products and services for

customers both domestically and globally

Unmanned Production Lines. SOURCE: HUAHUA

Digitized Production. SOURCE: HUAHUA

This innovation not only improved

production efficiency but also significantly reduced labor costs. Specifically:

Unmanned Production Lines: Beginning in

2018, HUAHUA has been dedicated to establishing unmanned production lines,

achieving advanced automation from zero components to assembly workstations.

This minimizes human intervention, increasing production efficiency.

Digitized Production: Implementing digital

production processes in their manufacturing facilities, HUAHUA ensures precise

control at every stage, guaranteeing high-quality and consistent products.

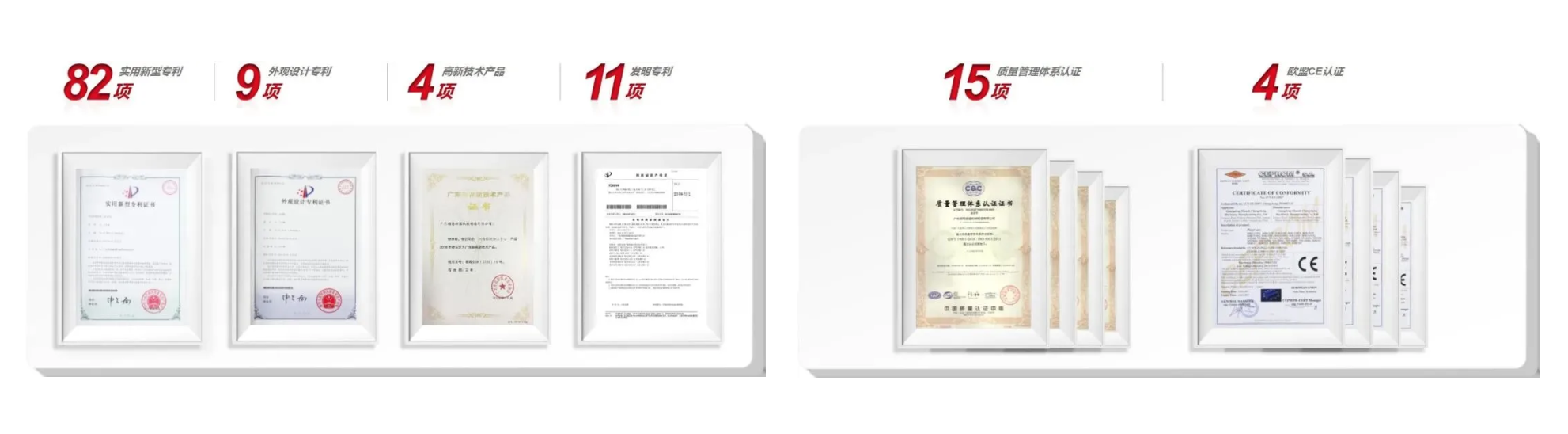

Currently, HUAHUA holds 82 utility model

patents, 9 design patents, 4 high-tech product certifications, 11 invention

patents, 15 quality management system certifications, and 4 EU CE

certifications, among other qualifications. The company has expressed its

commitment to transforming patented technologies into projects and further

incubating innovation in the future.

HUAHUA’s patents. SOURCE: HUAHUA

HUAHUA began developing into international

markets as early as 2014. The company prioritizes both domestic and overseas

markets, striving for balance and growth.

In response to global supply chain challenges and cost pressures, HUAHUA has implemented various measures to maintain its competitive edge. For instance, over the past two years, the brand has organized professional teams to conduct on-site investigations worldwide, gaining a deeper understanding of differences in furniture craftsmanship and applications across various countries and regions. These research findings have enabled HUAHUA to better tailor products to specific markets, enhancing the user experience.

Paper Cutter DX2600-D7L2. SOURCE: HUAHUA

The newly developed cutting system is

designed specifically for applications in wood furniture and paper packaging.

It features a user-friendly CNC system developed for operators without prior

CNC experience, offering ease of use, simplicity, powerful functionality, high

efficiency, and stable operation.

Convenient and fast user operation is made

possible by straightforward and clear parameters. The system’s adaptability is

enhanced by various options and parameters, while its input/output settings

facilitate easy use and maintenance.

In response to the unique demands of the

European market, HUAHUA has developed edge banding machines compliant with

European standards. These efforts have not only improved product quality but

also enhanced the company's market competitiveness.

Moreover, HUAHUA has achieved a high degree

of automation from zero components to assembly workstations through a digitized

production process, reducing human intervention and increasing production

efficiency.

HUAHUA’s headquarter SOURCE: HUAHUA

Through years of hard work, HUAHUA’s

products have reached European standards, and the company has achieved

remarkable success in international markets, with products selling well both

domestically and abroad. The company plans to further increase its international

market share in the coming years, with an expected product coverage of over 100

countries and regions by 2026.

Save the date: Mark your calendars

for the 55th China International Furniture Fair (Guangzhou), to be held in

Guangzhou Pazhou.

From March 18 to 21, 2025, the first phase

will feature Home Furniture, presenting all areas of home furnishings. The

second phase, from March 28 to 31, will spotlight the Office and Commercial

Space, the world's largest exhibition dedicated to office furniture and

commercial design.

Pre-register your E-entry code for

free now on our website!